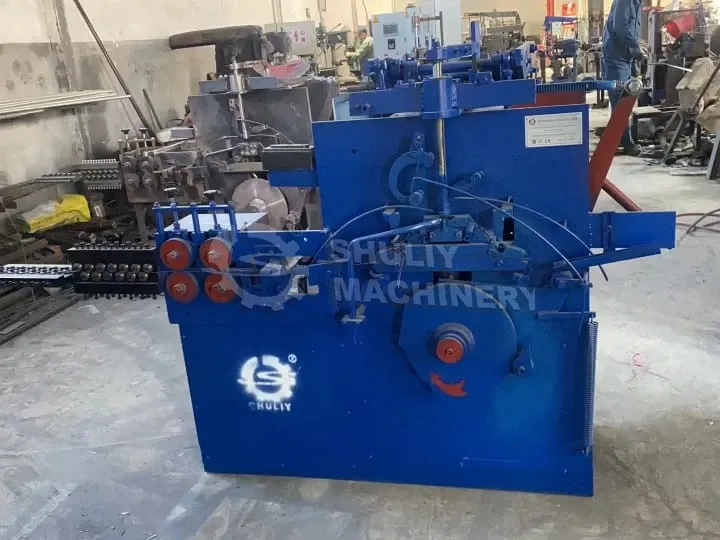

舒利衣架生产设备如何帮助海地制造金属衣架?

在海地,我们的挂钩生产设备帮助客户将金属挂钩的生产效率提高了30-40%,明显高于手工弯曲的效率。

他通过网站在线咨询联系我们,向我们发送了需求,我们的销售经理及时回复并提供了最合适的线材挂钩制造方案。接下来,请阅读以下详细内容。

海地的客户企业

这位海地客户是一家专注于金属制造的本地公司,主要生产和销售金属挂钩,面向国内市场。客户旨在通过引入自动化挂钩机提高整体盈利能力,提升生产效率,标准化挂钩尺寸,降低手工弯曲劳动成本。

客户对挂钩生产设备的要求

在采购前,客户明确了几个核心需求:

- 符合当地电力标准:220V / 60Hz / 三相电

- 成品挂钩尺寸:长40厘米,高20厘米

- 能够加工1.8–2.8毫米镀锌铁线/黑线

- 用于不同形状的额外模具

- 符合当地电力标准:220V / 60Hz / 三相电

- 成品挂钩尺寸:长40厘米,高20厘米

- 能够加工1.8–2.8毫米镀锌铁线/黑线

- 用于不同形状的额外模具

舒利为海地挂钩公司提供的解决方案

根据客户需求,舒利配置了一个挂钩成型机,功率1.5千瓦,产量达每分钟18-25个挂钩,兼顾效率与稳定性。

挂钩生产设备标配一个标准挂钩模具,并配备一套定制模具,灵活生产多种挂钩款式,增强市场竞争力。

挂钩生产设备吸引初期投资的优势

- 节省空间的设计,操作流程清晰

- 对操作员的最低技术要求,非常适合首次自动化的用户

- 稳定的成型工艺,挂钩尺寸一致

包装与交付目的地

考虑到长途海运,设备采用加固木箱包装,从我们天津仓库发出,确保运输安全。

同时,舒利提供清晰的运输文件和装箱单,方便后续清关。