Cost-effective solutions for clothes hanger production

As the global demand for hangers grows and the pressure on production costs increases, many clothes hanger manufacturers are focusing on how to reduce production costs while maintaining product quality.

Our company has responded to this market demand by focusing on the development and introduction of cost-effective, high-performance automatic hanger production equipment.

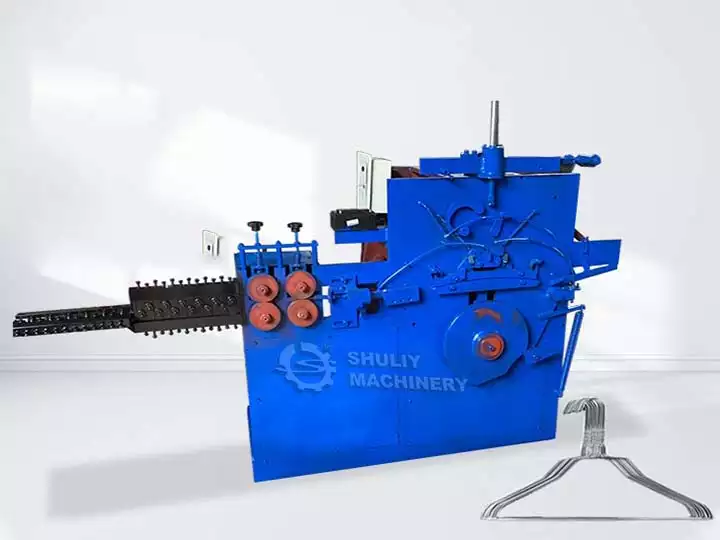

Cost-effective solution: Shuliy automatic clothes hanger machine

Automatic and efficient, saving labor costs

Our automatic hanger maker machine adopts an advanced PLC control system and intelligent induction technology, the integrated molding process from galvanized iron wire to various styles of hangers does not require too much manual intervention, significantly reducing labor input, thus achieving the purpose of cost-saving.

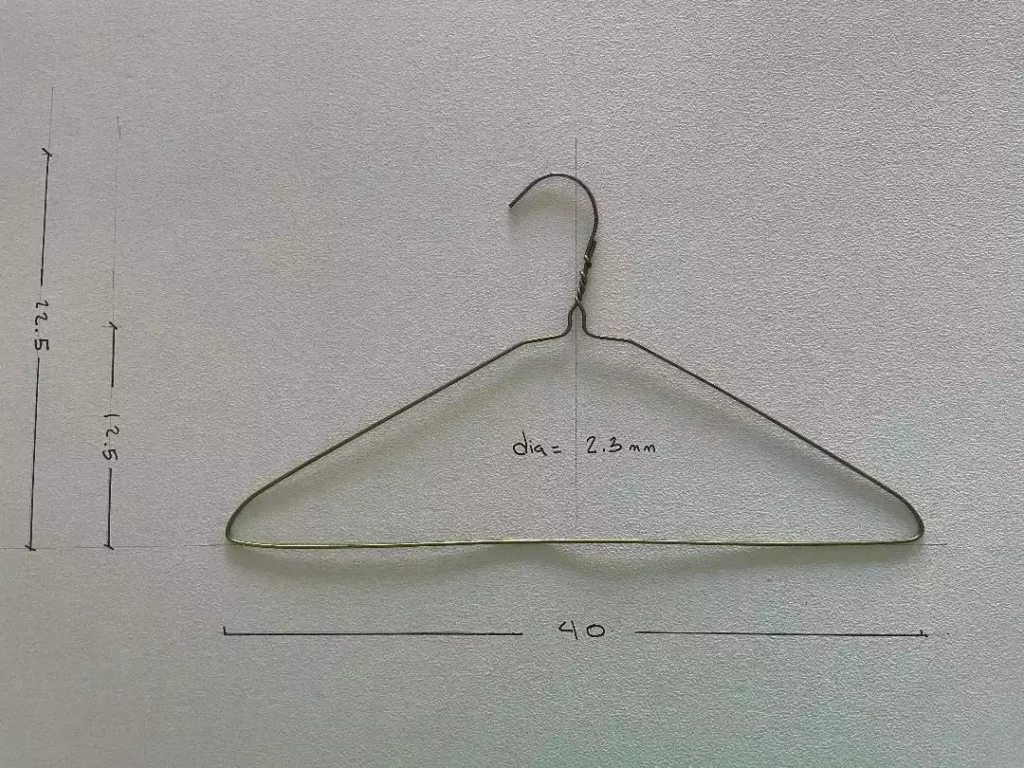

Precise control to reduce material loss

Through the design of precision molds and an accurate wire feeding system, the clothes hanger machine can complete each step of the operation accurately and precisely, effectively reducing the waste of raw materials and further lowering the cost.

Meanwhile, the excellent flexibility allows us to provide customized hanger design services to meet the needs of diversified markets.

Easy maintenance and long-term stability

The rational structure and easy maintenance of the wire hanger making machine greatly reduce the losses caused by malfunctions and downtimes, and ensure the continuous and efficient operation of the production line.

In addition, the hanger making equipment is made of high-quality wear-resistant materials with excellent durability, which maintains high performance under long-term use.

Get in touch with us for more machine details!

If you want a cost-effective solution for the production of hangers, contact us quickly. Tell us the shape of the hanger you want to produce, the raw material, the budget, etc. Our professional sales team will provide you with the optimal solution according to your needs.