Hanger Production Line | Clothes Hanger Making Machine

| Hanger production line capacity | 35-45pcs/min |

| Hanger size | 11-19 inches |

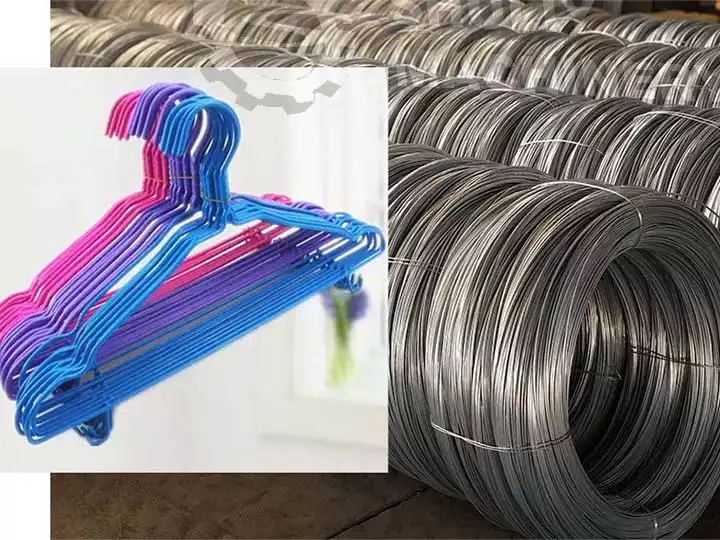

| Raw materials | Plating lines, iron wire, low carbon, galvanized, PVC wire, etc |

| Baking temperature | 180 degree |

| Baking time | 15-20min/time |

| Equipment used in the clothes hanger produciton line | Pay-off machine, hanger forming machine, spray machine, powder recycling machine, drying machine |

You can now ask our project managers for technical details

The clothes hanger production line is mainly used to produce various types of household-type clothes hangers. The clothes hanger is an essential household item in life. And hanger machine is an essential machine to produce hangers. If you want to involve invest in the daily necessities industry, investing in the clothes hanger making machine is a good choice.

Our hanger machine is very popular all over the world, such as in UAE, Australia, Pakistan, Kazakhstan, Cambodia, Morocco, Mexico, Sweden, Saudi Arabia, Sri Lanka, Spain, Yemen, Uzbekistan, etc. If you are interested in this machine, welcome to call us!

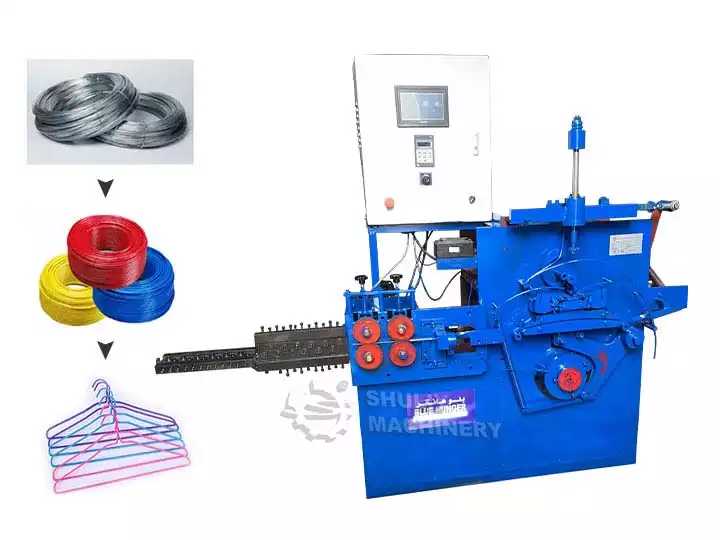

What material is used to make hangers?

In the fully automatic hanger production line, the raw materials used to produce the hanger are actually very simple. Such as plating lines, iron wire, low carbon, galvanized, PVC wire, etc. If you have doubts about your raw materials, welcome to contact us for classifications!

How do you manufacture hangers?

To produce hangers in a hanger production line, the following steps are followed.

First, you need to put the wire (raw material) on the payoff spool, and the wire is conveyed by the payoff machine to the clothes hanger machine entrance.

Then, the wire goes forward along the spool wheel of the hanger machine, and then the hanger is made at the hanger forming. The hanger will come forward with the support rod when it is finished.

Next, the painting process is carried out. Choose the color you want for painting.

Finally, recycle the plastic powder and dry the hangers.

Equipment used in the clothes hanger production line

In the complete wire hanger manufacturing line, you need to use the following machines:

Introduction of each machine

This machine is at the very beginning of the whole production line. Its main function is to put the wire on this machine and transport the wire forward along the track of the hanger machine.

Although the structure is simple, it is also an indispensable part of the whole production line.

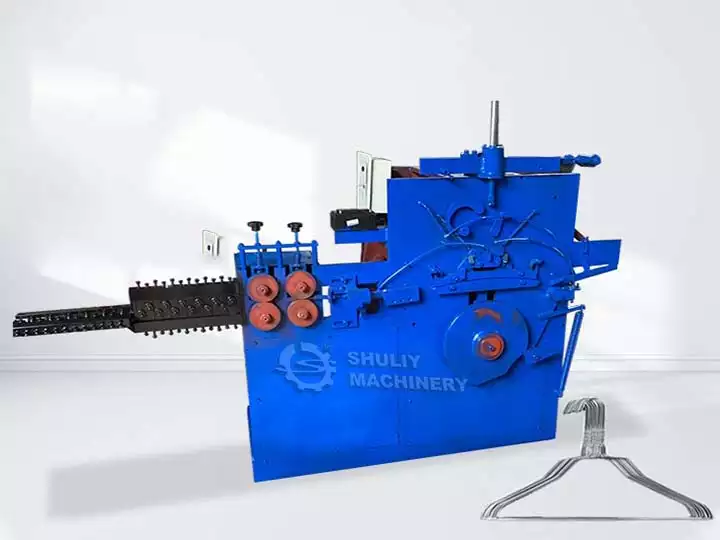

The wire hanger machine is the core, mainly to produce various types of hangers (what customers want). It can produce 35-45 pcs/min and the size of the hangers is 11-19 inches.

In addition, we can also customize the clothes hanger making machine according to your requirements, i.e. to produce the hanger you need.

This step has two pieces of equipment, the powder spray machine and the powder recycling machine. As you can see from the name, one is the machine that performs powder spraying and the other is the machine that performs recycling.

They are usually used together. The main function: 1)to spray the hanger; 2)to recycle the excess powder to protect the environment.

This is the last step, drying the hanger after spraying. The baking temperature is 180 degrees Celsius, and the time is 15-20 minutes once.

The main reason for drying is that this step can make the hanger color stick longer.

Machine list in the fully automatic hanger production line

| Item | Model | Parameter |

| Wire hanger making machine | SLPT-400 | Power: 1.5kw Capacity: 35-45pcs/minute Weight: 700kg Dimension: 1800*800*1650mm |

| Spray machine | DMT-23580 | Weight: 25kg |

| Powder recycling machine | PRM-4 | Power: 3kW Size: 1.5*1.1*2m |

| Oven machine | DMSL-300 | Machine size: 3*2.0*1.8m Baking temperature: 180 degrees Baking time: 15-20min/time |

When you choose the machine, we can also provide the powder and wires. We have different colors of powder for your choice. Moreover, we have wires, like 1.8-3.0mm galvanized wire for customers to choose from.

Advantages of the wire hanger production line

- The whole process is easy to understand and very user-friendly.

- High productivity, and a wide range of hanger types can be produced.

- Good quality machine, stable operation and easy maintenance.

- The clothes hanger machine is made up of iron plate material and has a long service life.

- Electric control and manual fine-tuning cooperate with each other, which is more convenient to use.

- Using double pressure liquid oil cylinder, the accuracy is more accurate.

Shuliy Machinery – the credited hanger machine manufacturer & supplier

We, Shuliy Machinery, are a reputable company in both domestic and international markets, with the following main points.

Good quality machine and the right price. When choosing products, not only should the price be good, but also the quality should be good. And our products meet this point.

Support machine customization. Because not all customers want to produce the machine factory has, and customization will be able to produce the machine that customers want. It’s a win-win for both sides.

After-sales service. After-sales service is also a top priority. Our staff will provide customers with timely and effective after-sales service, which is one of our features.

Is it profitable to invest in the hanger production line?

The answer is of course yes. Because hangers belong to household items, they are an indispensable part of daily life. There are also many manufacturers, so it is vital to choose the right clothes hanger making machine. Because it is necessary to produce high-quality hangers so that they can quickly open market sales. At the same time, there will be a good reputation, which lays the foundation for subsequent development.

If you need any assistance, welcome to contact us!

Attentions when running the hanger production line

- Please operate the machine under the condition that the molding machine and personal safety are guaranteed.

- The power supply of the machine is three-phase and five-wire, which are three phase wires, one neutral wire and one ground wire. The line voltage is 380V, the phase voltage is 220V, and the total power is about 2.2KW, ensuring reliable grounding.

- When the molding machine is powered on, it is not allowed to forcibly rotate the feeding servo motor, otherwise the servo controller will be damaged. If you need to rotate the feeding servo motor, please use the buttons of “jog feeding”, “jog return” and “manual feeding” in the “production monitoring” of the man-machine interface to perform related operations.

Successful case: Automatic hanger production process line exported to UAE

A customer from the UAE contacted us because of our customization service. He wanted to buy a complete hanger production line and wanted to produce hanger with butterfly model. After our sales manager learned about it, he gave him a detailed introduction of the machine, and he was very satisfied with it. So the two sides had a win-win cooperation. In the picture below, we are loading the goods.