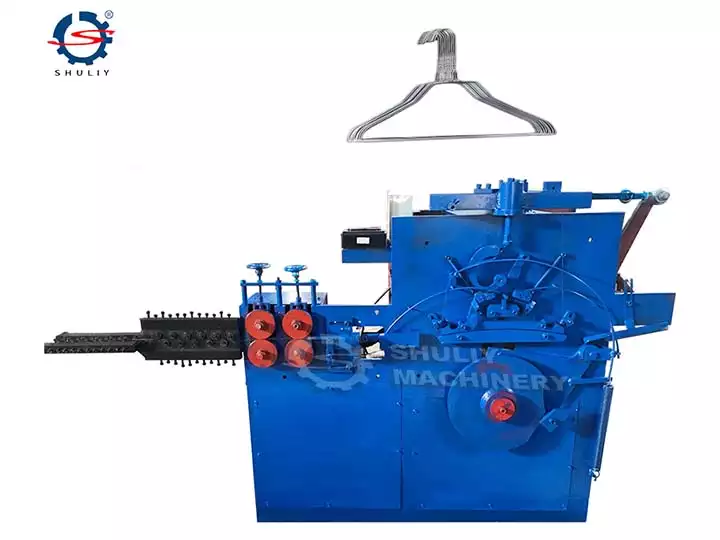

Plastic wire hanger making machine sold to Saudi Arabia again

In April 2023, a customer from Saudi Arabia purchased a plastic wire hanger making machine with a PLC system for making PVC-coated & galvanized wire clothes hangers.

What was the reason for this Saudi Arabian customer to purchase a plastic hanger making machine?

This Saudi Arabian customer needed an efficient automated clothes hanger machine to help him process large quantities of PVC wire and galvanized iron wire to help him make a profit.

What kind of plastic wire hanger making machine did we recommend to the customer to meet his needs?

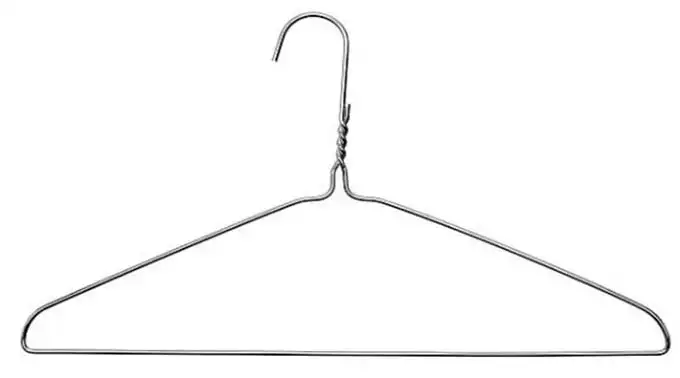

A high-performance hanger machine is recommended. This coat hanger machine uses the latest PLC control system, and the raw materials used can be PVC wire and galvanized wire, Also, various types of hangers can be produced. This kind of machine must fit his needs.

Why is this control system beneficial to customers?

This plastic wire hanger making machine is an automated machine controlled by a PLC control system. This means that customers can easily operate the hanger machine through a touchscreen interface.

In addition, the PLC control system can automatically recognize the size and material of the hanger and adjust it automatically according to the different types.

The use of this automated control system can greatly improve work efficiency, reduce labor costs and operational errors, and make customers more convenient and efficient in their daily business.

PLC plastic wire hanger making machine PI for the client from Saudi Arabia

Notes: voltage for this machine: 380V 60HZ 3P

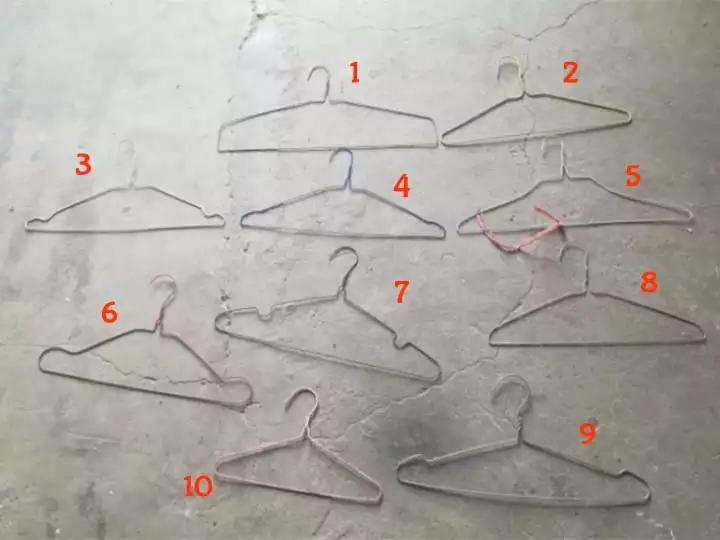

The hanger type that the customer wants to produce is No.2 shown in the left picture.