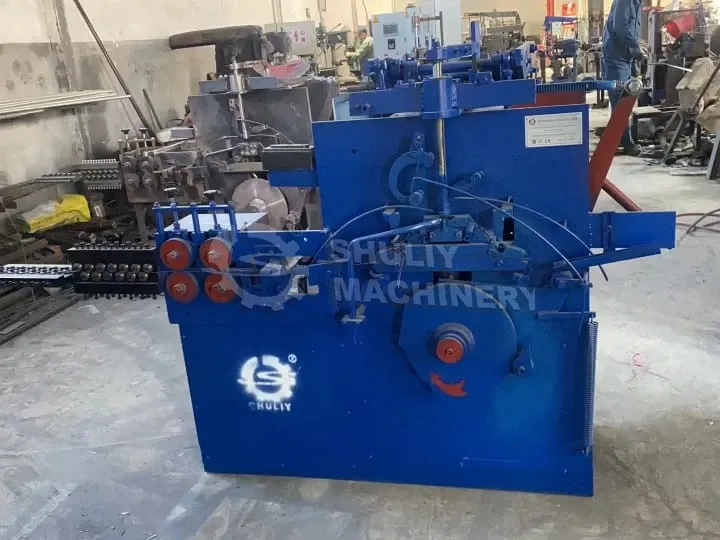

PLC hanger maker machine for Benin galvanized wire & plastic hangers production

We are very happy to share with you that a customer from Benin has purchased our hanger maker machine for hanger production. This machine is capable of producing both galvanized wire and PVC-coated hangers with high efficiency and flexibility, which is very suitable for the customer’s production needs.

Reasons for choosing PLC hanger maker machine

The customer chooses PLC controlled hanger machine mainly because it has intelligent control system, which can be flexibly adjusted according to different raw materials to produce different types of hangers.

The customer’s raw materials include galvanized iron wire and coated wire, and the PLC hanger making machine is able to support the production of both materials with easy operation and high precision. The versatility of the machine provides customers with great convenience and can easily cope with the production needs of different types of hangers.

The raw materials of Benin customers include galvanized iron wire and coated wire, PLC hanger machine just meets the hanger production requirements of these two kinds of raw materials.

Package and delivery of hanger maker machine

We choose to wrap the machine firstly and then pack it in wooden case, which can well guarantee the safety of the machine during the sea transportation.

Customer satisfaction and after-sales service

After purchasing and installing the PLC hanger maker machine, the Benin customer is very satisfied with its performance.

The machine’s efficient and stable production allowed the customer to save a lot of time and labor cost, and increase production capacity. In addition, Shuliy provided the customer with perfect after-sales service, regular equipment inspection and maintenance to ensure the long-term efficient operation of the machine.

The customer highly praised the professionalism and after-sales service of Shuliy.