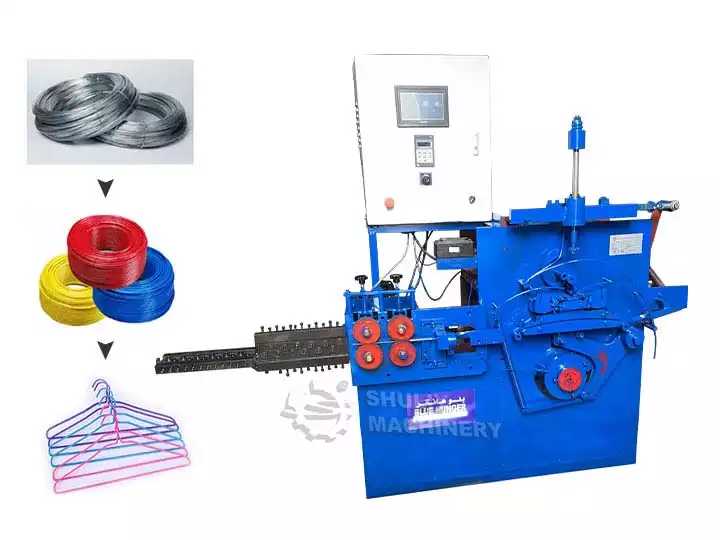

Coated Hanger Production Line | Plastic Hanger Manufacturing Process

| Coated hanger production line capacity | 35-45pcs/min |

| Hanger size | 11-19 inches |

| Coated materials | PVC, PE, PP, PA, and other plastic-type coatings |

| Machines used in the coated hanger production line | Rolling machine, plastic extruder, cooling water tank, storage wire machine, plastic hanger making machine |

You can now ask our project managers for technical details

The coated hanger production line takes the wire wrapped with the coat first, and then a plastic hanger machine is used for the hanger production.

Usually, it is coated with PVC, PE, PP, PA, and other plastic-type coatings. The hanger produced in this way has a longer service life because it is isolated from moisture when drying clothes.

Besides, the whole production process is easy to operate, efficient, and smooth to run. If you want to PVC-coated hangers, investing in this line is a good choice. Please contact us for more details!

Introduction of the plastic hanger manufacturing process

The whole production process: first coat the wire, then use the coat hanger machine to produce the coated hangers.

Steps of the coated hanger production line

Step 1: Rolling machine

Put the wire on the machine, and follow a certain track to the entrance of the main machine of the next gluing machine.

Step 2: Plastic extruder

This step is mainly to carry out the wire coating, optional PVC, PE, PP, PA, and other plastic materials.

Step 3: Cooling tank & storage wire

The coated wire is cooled to make the plastic more comfortable and durable. After this, use the storage wire machine to store the coated wire.

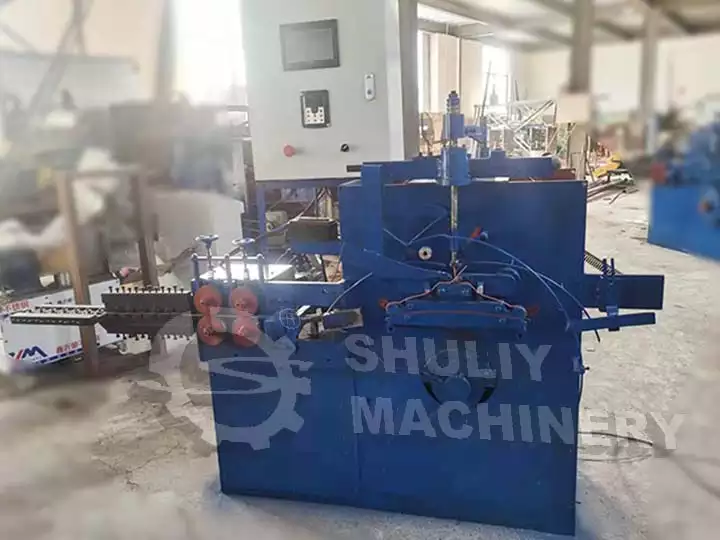

Step 4: Plastic hanger making machine

Use the Shuliy hanger machine to make the coated hanger, and various shapes of the hanger can be made according to the customer’s requirement.

Machine list in the coated hanger production line

| Item | Model | Quantity | Parameter |

| Rolling machine | / | 1 set | Contains two wire reels Motor:2.2kW Inverter motor |

| Plastic extruder | / | 1 set | Screw diameter: 65mm Motor:7.5kW Inverter motor |

| Cooling water tank | / | 3 m(length) | Material: stainless steel Water pump: 1 set |

| Storage wire machine | / | 1set | Diameter: 550mm |

| Plastic hanger making machine | SLPT-400 | 1 set | Power: 1.5kw Capacity: 35-45pcs/minute Weight: 700kg Dimension: 1800*800*1650mm |

The whole coated plastic hanger production line can produce coated hangers with the features of high efficiency and long service life. If you are interested in this plastic hanger manufacturing process, welcome to contact us at any time. And we’ll reply as soon as possible!

Spotlights of the fully automatic coated plastic hanger production line

- Diverse coating materials. The outer layer can be wrapped with different plastics such as PVC, PE, PP, PA, etc.

- High efficiency. The plastic hanger machine can produce 35-45 hangers per minute.

- Customized service. We can customize the hanger forming machine according to the shape of the hanger required by customers.

- The produced hangers have dense coatings, even thickness of the plastic layer, stable size, and clean appearance.

- Fully automatic, save labor and time cost, so the coated hanger production line is a good choice for investment.

Why use the coated hangers?

Compared with other types of hangers, these hangers last longer and are friendly to clothes. And because of the presence of the coatings, the hanger will not be damaged after accidentally dropping the hanger on the floor. So there is some protection for the hangers as well.

And for the rainy climate, hangers with plastic PVC coating are more popular. So, there is still a potential market for coated hangers. If you are interested in investing in the coated hanger production line, get in touch with us for more details!

What benefits can you get after using the plastic hanger making machine?

- High-quality plastic hangers. Because our coated hanger production line is a production of top-quality hangers, you can get good-quality hangers by purchasing and using our production line.

- Improve your company’s reputation. Nowadays, the market competition is very fierce, and the excellent hangers you produce can help you win the praise from your customers. Thus, it helps improve your company’s reputation and forms a good company image to the outside world.

- Double your profit. With the addition of the above two points, your sales will definitely be ahead of the same type of companies. Then, naturally, your profit will also be greatly increased.

Services provided by Shuliy Machinery

- Professional team service. Our sales staff are all trained strictly before they can be employed. So all have a very full understanding of the coated hanger production line and can provide the optimal solution according to your requirements.

- Online guidance service. After the sale of the machine, if you need to conduct an online guidance service, we can meet you.

- Machine operating instructions. Before sending the machine, we will store the instruction manual together with the machine, which can help you to use the machine better.

- Pre-sale, on-sale, and after-sale service. After you ask for the machine, we will provide complete sales service according to your needs.

- Customization service. Shuliy Machinery can customize the wire hanger making machine according to the shape of the hanger you want to produce.

Maintenance of the plastic hanger making machine

- Please cut off the power supply when the machine is not working. And forbid to power on for a long time and not use it.

- Refuel 2 times per shift, add it to various oil eyes, and you can start it for trial.

- Regularly (2 months) check the oil amount in the reduction box. When the oil amount is not enough, please add enough gear oil.

- Keep the machine clean, dry, and ventilated.

- Regularly refuel the transmission part (moving mechanism gear, etc.).

Successful case: the automatic powder coated hanger production line for sale to Australia

This Australian customer was specifically looking for the production of plastic-coated hangers. Because of the climate features in Australia, it is more economical to use plastic-coated hangers.

Therefore, after seeing our machines on the website, the Australian customer contacted us and asked us about the plastic-coated hanger production line. Our sales manager introduced the machine patiently and carefully.

After understanding the machine, the Australian customer was very satisfied and signed the order immediately. After completing the production, the customer also asked for a trial run of the machine. He was also very pleased with the result of the test machine. Then we arranged the delivery.

Working process video of the coated hanger production line

Related hanger production line

This clothes hanger production line can also produce excellent hangers for drying clothes. If you want to know more details, please go through this article, and also contact us!