A customer from Oman bought wire hanger production line

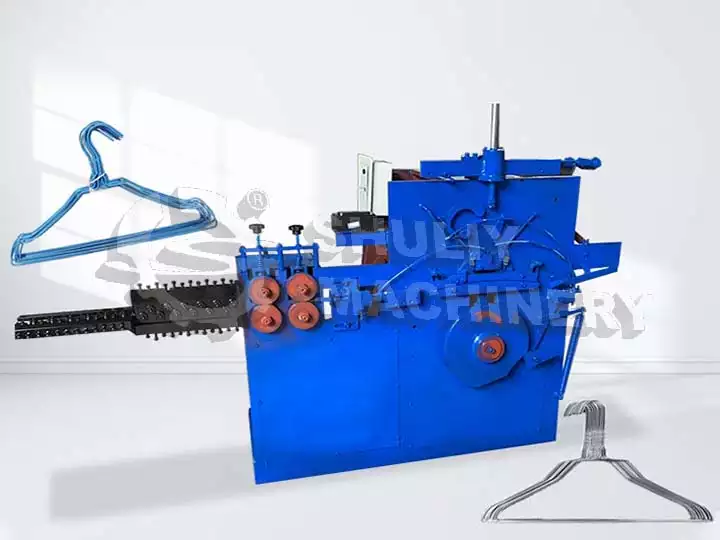

Breaking news! A customer from Oman has ordered a complete galvanized wire hanger production line from us. The clothes hanger line is mainly used to produce galvanized hangers which are then painted into pink hangers for sale.

Basic information about this Omani client

This customer runs a local company and is a local distributor and supplier of machinery and equipment. This time he searched for a hanger machine for his end customer.

Questions about the wire hanger production line from this Omani customer

1. How much powder is required for each one-ton metal wire?

One ton of powder can make around 1.6 million hangers.

2. Could you give advice for machine organizing production overflow?

We will provide the manual after the order is confirmed. We also could provide free online technical support!

3. I need good quality, how do you promise the machine quality?

We focus on this field for over 10 years, our machines are of high quality, and customer feedback is very good. Besides, we test and video the machine before delivery for your confirmation.

4. I want to make 1.8mm & 2.3mm hangers, one machine or two machines?

If you want to make 1.8mm & 2.3mm hangers together, two machines are suitable. If not, one machine can meet your needs.

Machine list for this Omani client

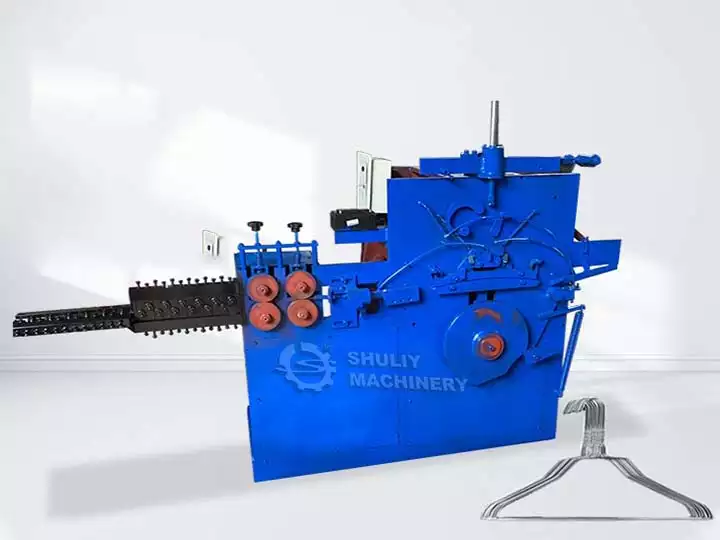

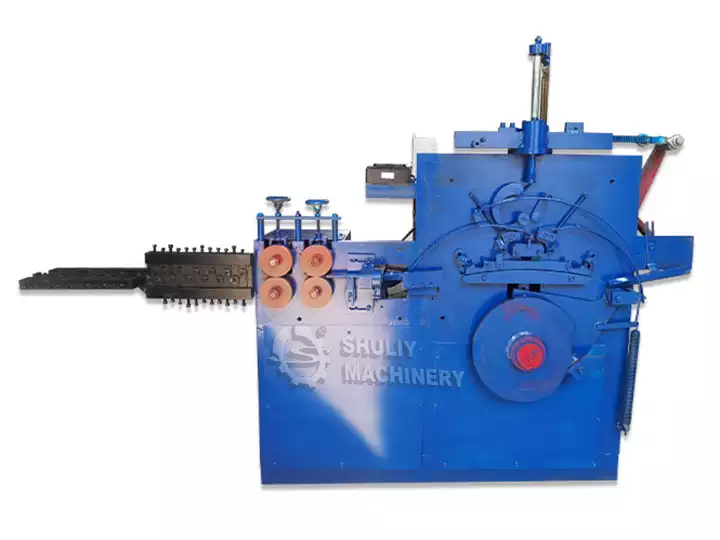

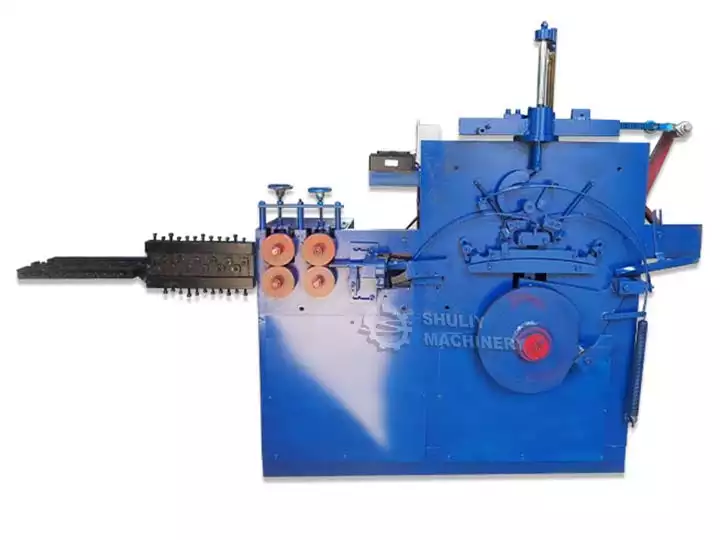

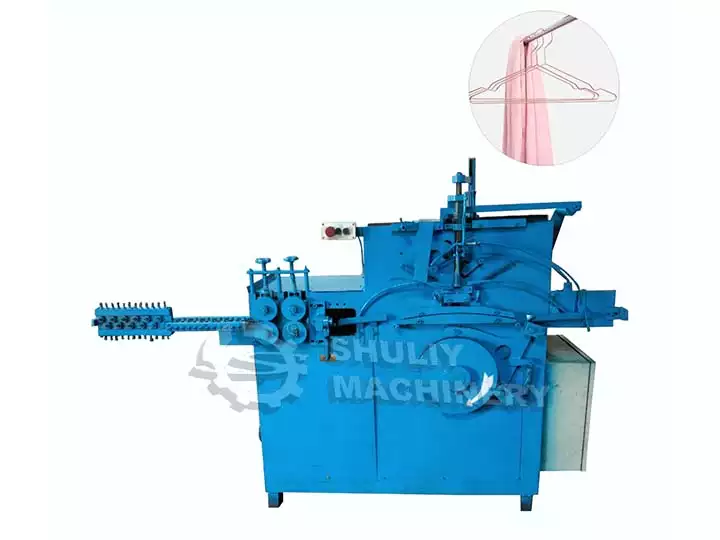

| Item | Model | Parameter | QTY |

| Galvanized wire hanger machine  | SLPT-400 | Power: 1.5kw Capacity: 30-40pcs/minute Weight: 700KG Dimension: 1800*800*1650mm Total 3 molds, 3 wire stands | 2 sets |

Spray machine | DMT-23580 | Weight: 25kg | 1 pc |

Powder recycling machine | PRM-2 | Power: 3kw Size: 1.5*1. 1*2m | 1 pc |

Oven machine | DMSL-300 | Machine size: 3*2. 1*2m Baking temperature:180 degree Baking time: 15-20min/time Electric heating | 1 pc |

Hanger stand | DMS-3 | Inside the hanger oven for holding hangers | 2 pcs |

Powder | Powder(blue) | 1 ton |

Notes to galvanized wire hanger production line:

- 2 sets of Shuliy wire hanger machines totally have 3 moulds and 3 hanger feeder rolls.

- The voltage of the hanger machine is 380V 50HZ,3 phase.

- The oven machine includes 1 hanger stand, and also another 2 hanger stands are needed.