What’s the plastic hanger manufacturing process?

For the plastic hanger manufacturing process, according to our experience, our hanger making machine can bring you a faster and more rationalized production solution. There are different production methods depending on the raw materials. The details are as follows:

Make coated hangers with galvanized wires

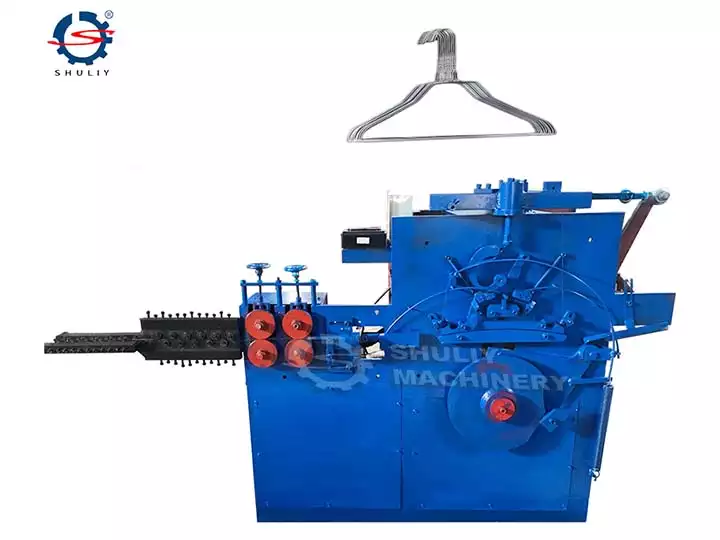

For the production of coated hangers using galvanized iron wire as raw material, Shuliy hanger machine provides an efficient production process.

Firstly, the galvanized iron wire is bent and shaped by the hanger machine to form the basic structure of the hanger.

Afterward, the hangers are coated by a spraying machine to ensure a uniform and durable coating.

Finally, the hangers are dried by drying equipment to cure the coating and improve the quality.

Plastic hangers production by coated wires

Another way to produce coated hangers is to use coated wire directly as raw material and produce it through Shuliy’s PLC hanger machine. This kind of plastic hanger manufacturing process greatly simplifies the production process.

The PLC coat hanger machine can be programmed according to customer requirements to produce coated hangers of various shapes quickly and precisely. Its highly automated nature makes the production process more efficient and controllable.

As a company specializing in the manufacture of hanger machinery, Shuliy provides its customers with superior products and excellent service. Whether you use galvanized iron wire or coated wire, Shuliy coat hanger machine is your partner for success. If you are interested, welcome to contact me for more details!